Panasonic Announces Development of Organic CMOS Sensor that Realizes Good Color Reproduction under all Kinds of Light

Myth of the Organic Sensor

10 year after the joint Panasonic and Fujifilm announcement, where the organic sensor was first unveiled to the masses with great optimism and claims of glorious performances and dynamic range, we haven’t seen anything coming to the market, expect for a camcorder prototype shown by Panasonic back in 2019.

The last update we got was back in October 2021, when Panasonic unveiled a 35MP organic Super35 CMOS sensor with global shutter.

Well, today we got another update from Panasonic, where they announced the “development of organic CMOS image sensor technology that realizes good color reproduction even under all kinds of light sources“. You can read the full press release below.

Is Fujifilm Still Involved?

Unlike the first announcement in 2013, that was made by Panasonic and Fujifilm together, this time it’s only Panasonic, who released a press release regarding the organic sensor development.

So the question I guess is if Fujifilm has pulled out of the organic sensor development.

The last statement in this regard comes from Panasonic, who in October 2018 said they are still working on it with Fujifilm.

So at least until 2018, Fujifilm and Panasonic did work on it together, but I don’t know if that’s the case still today. I will try to figure that out and in case let you know.

The Organic Sensor Novel – A Summary:

- June 2013: Fujifilm and Panasonic announced the organic sensor development

- December 2014: Our sources told us here, that there is a crucial problem to be solved with the organic sensor: heat generation (and battery drain)

- December 2014: Top Fujifilm Managers confirmed, that the organic sensor is “still well ahead of us.”

- October 2015: 43rumors broke the rumor here, that it will still take a 2 or 3 years before the organic sensor will be ready for mass production.

- February 2016: Panasonic announced that, along with Fujifilm, they are developing an organic sensor with global shutter and impressive 123dB (!!!) dynamic range.

- February 2016: Fujifilm management says: “We don’t have any specific plans of incorporating an organic sensor into our products at the moment, but yes we are observing the progress of this technology. As of today, there would be No benefits to using an organic sensor. Our X-Trans III sensor is superior to the currently available organic sensor.”

- February 2017: Panasonic announces the world’s first organic CMOS image sensor with electrically controllable near-infrared light sensitivity. However, unlike in previous press-releases, this time Fujifilm isn’t mentioned.

- February 2017: Fujifilm Announces Development of World’s fastest Organic CMOS Circuit For Multi-bit flexible Temperature Sensor

- August 2017: Development of Wide Dynamic Range and Global Shutter Technology for Organic Photoconductive Film Image Sensor (Panasonic)

- Febraury 2018: Panasonic Announces 8K 36 Megapixel Global Shutter Organic Sensor… and Time To Stop Sony’s Sensor Hegemony

- October 2018: Panasonic Says Organic Sensor Cooperation with Fujifilm Continues. Mass Production Will Take a Bit more Time

- September 2019: Panasonic shows first Camcorder featuring 8K organic sensor

- October 2021: Panasonic Unveils 35MP Organic Super35 CMOS Sensor with Global Shutter and Great Dynamic Range

- March 2023: Panasonic Announces Development of Organic CMOS Sensor that Realizes Good Color Reproduction under all Kinds of Light

Press Release

Development of organic CMOS image sensor technology that realizes good color reproduction even under all kinds of light sources

Panasonic Holdings Co., Ltd. has developed a good color reproduction technology that suppresses color mixing by thin filming of the photoelectric conversion layer due to the high light absorption rate of the organic film and electrical pixel separation technology. In this technology, with a unique stacking structure that completely independents an organic thin film that performs photoelectric conversion and a circuit part that accumulates and reads charge, can reduce sensitivity and achieve low mixed-color spectror characteristics in the wavelength range outside the target of green, red, and blue pixels? It is possible to reproduce accurate colors regardless of the type of light source.

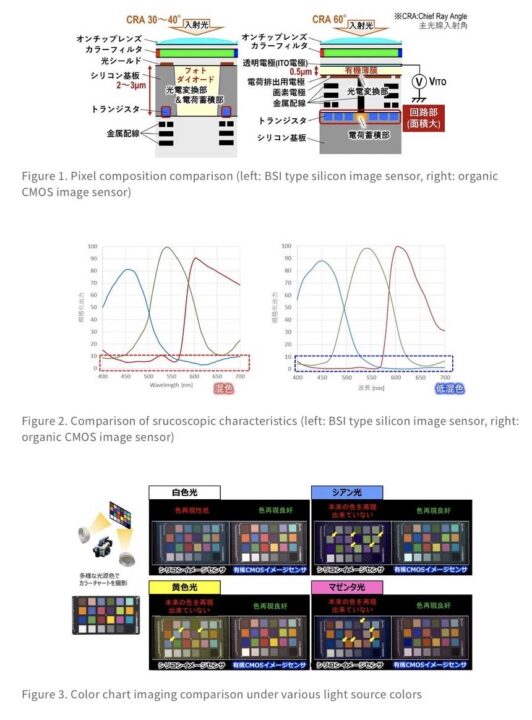

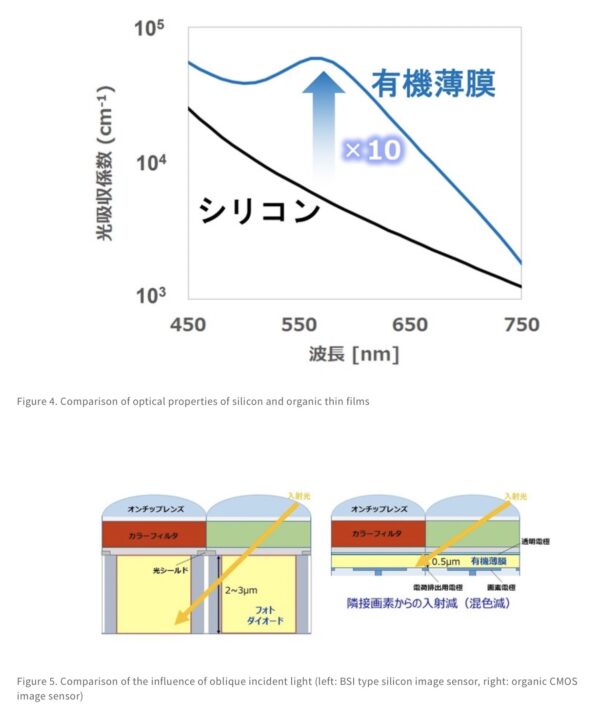

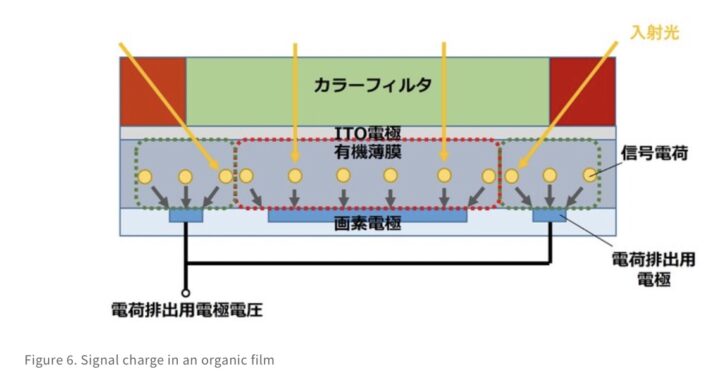

[Overview] Conventional Bayer array silicon image sensors do not have enough color separation performance in green, red, and blue, so for example, under light sources that have peaks at specific wavelengths such as cyan light and magenta light, accurate color reproduction and color recognition and judgment are difficult. It was difficult.Our organic CMOS image sensor is composed of an organic thin film with an organic thin film in the photoelectric conversion part that converts light into electrical signals, and the function of accumulating and reading signal charges is completely independent in the lower circuit part (Figure 1). This makes it possible to have photoelectric conversion characteristics that do not depend on the physical properties of silicon, unlike conventional silicon image sensors. In addition, thin filmization has been realized by organic film with high light absorption rate ((1) photoelectric conversion layer thin film). By installing an electrode for charge discharge at the boundary of the pixel, the signal charge by the incident light at the pixel boundary is discharged and the intrusion of the signal charge from adjacent pixels is suppressed ((2) Electrical pixel separation). In addition, the lower part of the organic thin film is covered with a pixel electrode to collect the signal charge generated by the organic thin film and the electrode for discharging the aforementioned charge, so it suppresses the transmission of incident light that could not be absorbed by the organic thin film to the circuit part ((3) Light transparency Over-repression structure). With the above technology, it is possible to suppress the light and signal charges entering from adjacent pixels. Therefore, the mixed color can be kept low enough as shown in the spectral characteristics shown in Figure 2, and accurate color reproduction is realized regardless of the color (spectrum) of the light source (Figure 3).

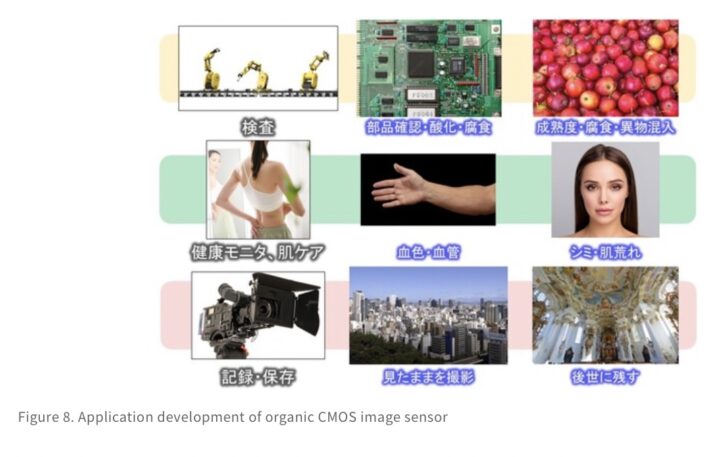

With this technology, for example, it is possible to reproduce and inspect accurate colors even in environments where it is difficult for image sensors to reproduce the original color, such as plant factories that use magenta light. In addition, you can expect accurate color reproduction of substances with microscopic color changes such as living bodies, so you can expect it to be applied to management of skin condition, monitor health status, and check fruits and vegetables.

In addition, together with the high saturation characteristics of our organic CMOS image sensor and the global shutter function (*1), we will contribute to the construction of a highly robust imaging system that is resistant to changes in the type, illuminance, and speed of the light source

(1) “photoelectric conversion film thin film technology” by up to 10 times light absorption

(2) “Electrical pixel separation technology” that emits unnecessary electric charges at the pixel boundary

(3) “Light transmission suppression structure” that suppresses light from transmitting in the photoelectric conversion part

(1) “photoelectric conversion layer thin filmization technology” by up to 10 times light absorption

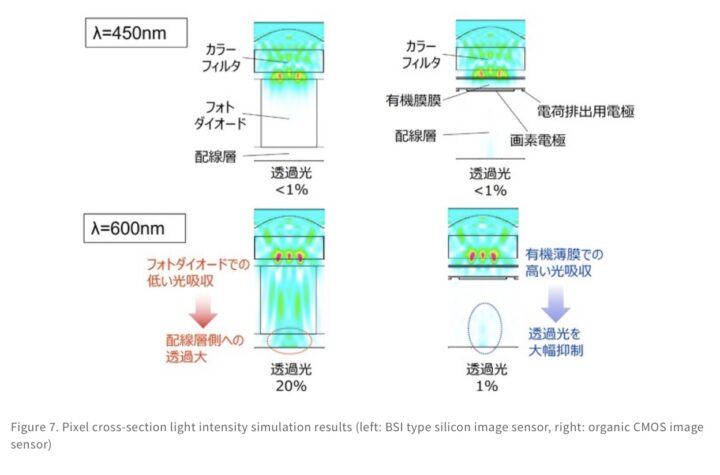

The organic thin film developed this time has a maximum light absorption coefficient of about 10 times higher than silicon (Figure 4), so the distance required for light absorption can be shortened. As a result, it is possible to design a thin organic film against silicon photodiodes, and it is possible to reduce oblique incident light from adjacent pixels, which is a factor of color mixing, in principle (Figure 5).

(2) “Electrical pixel separation technology” that emits unnecessary electric charges at the pixel boundary

The charge generated at the pixel boundary part also includes the signal charge derived from adjacent pixels due to oblique incident light, so it is a factor in so-called color mixing and resolution reduction. Conventional silicon image sensors have a light shielding layer at the boundary of the pixel to prevent oblique incident light, but there are insufficient aspects such as the light reflected by the light shielding layer becomes stray and enters the adjacent pixels, and light turns around the light shielding layer by diffraction. It was.

Therefore, by arranging electrodes for charge discharge at the boundary of the pixel, we have developed a structure that discharges the signal charge from the incident light at the pixel boundary and suppresses the intrusion of signal charges from adjacent pixels. By installing a charge emission electrode, the charge generated at the pixel boundary is discharged, so the above image quality deterioration can be suppressed (Figure 6).

(3) “Light transmission suppression structure” that suppresses light from transmitting in the photoelectric conversion part

The light emitted into the photoelectric conversion part (photodiodes in silicon image sensors and organic thin films in organic CMOS image sensors) is photoelectric converted and converted to signal charges. However, some light is not converted to photoelectric and is transmitted and is a cause of mixing. In particular, red light with a long wavelength and low energy is easier to transmit than blue light, and the impact is greater.

Conventional silicon image sensors transmit about 20% of light with a wavelength of 600 nm, but with the organic CMOS image sensor developed, transmission was significantly suppressed to about 1% (Figure 7). The lower part of the organic thin film is a structure covered with a pixel electrode for collecting signal charges and the electrode for discharging the aforementioned charge. Therefore, the incident light that could not be absorbed by the organic thin film is absorbed by absorbing or reflecting with the electrode and passing through the organic thin film again. In addition, since there is little between the pixel electrode and the electrode for discharge, it is difficult for light to penetrate to the lower part of the organic film.

In the future, we will propose these organic CMOS image sensor technologies for a wide range of applications such as professional broadcast cameras, security cameras, industrial inspection cameras, and in-vehicle cameras, and a highly robust imaging system that is resistant to light source types, illuminance, and speed changes. I will contribute to the construction of Mu.

※1 [Press Release] Developed 8K high-resolution, high-performance global shutter imaging technology using a CMOS image sensor using organic thin films

https://news.panasonic.com/jp/press/jn180214-1

It is one of the arrays of color filters installed in each pixel to obtain color information, and is repeatedly arranged in 4-pixel units of RGGB. Each pixel has only one of the color information of R, G, or B, so it interpolating other color information from the surrounding pixels.

[2] Mixed color

The signal of a certain pixel is mixed into the adjacent pixel. In the image sensor of the bayer array, the color is different depending on the adjacent pixels, so the color signal is mixed and the exact color cannot be reproduced.

[3] Color reproducibility

How much can the image actually reproduce the color of the subject? It is affected by the spectral characteristics of the image sensor, the spectrum of the light source, and the reflection spectrum of the subject. [Contact] Panasonic Holdings Corporation

Public Relations Email: crdpress@ml.jp.panasonic.com

via Panasonic