Fujifilm X-T6, X-Pro4, X-H3, X100VII with 46 Megapixel Sensor? – Speculation Based on Fujifilm GFX180

We told you that there will be a Fujifilm GFX180. it won’t happen very soon, but it will come at some point.

And the Fujifilm GFX180 might even tell us more about the future of the Fujifilm APS-C system and the X-Trans 6 sensor.

Why?

Well, Fujifilm usually uses the same sensor for the X system and GFX system, with the only difference that the GFX sensor is about 4 times bigger.

This means:

- 26MP APS-C sensor (X-S20 & Co) = 102MP on GFX (GFX100S & Co)

Now, if we were to apply the same logic to the rumored Fujifilm GFX180 sensor, then we would get this

- 180MP on GFX = about 45.8MP on APS-C

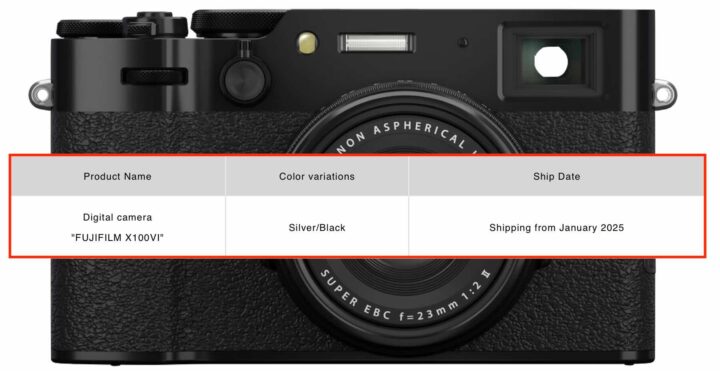

This means that I would not be surprised if the Fujifilm X-T6, but also the Fujifilm X-Pro4, the Fujifilm X-T60, the Fujifilm X-E6, Fujifilm X100VI and the Fujifilm X-H3 would come with a 46 megapixel sensor.

This means a slight increase in resolution for APS-C, which is definitely welcome.

Other questions remain open, with the main one being if it will be a DGO or DCG sensor.

Regarding the “more megapixel are bad for low light photography”, make sure this read this debunking article.

Follow FujiRumors on Patreon, Facebook, Instagram, RSS-feed, Youtube, Flipboard and Twitter

The Best Fujifilm Communities

- Fujifilm Film Simulation Group

- Fujifilm X-T Shooters Group

- Fujifilm X100 Shooters Group

- Fujifilm GFX Shooters Group

- Fujifilm X-Pro Shooters Group

- Fujifilm X-H Shooters Group

- Fujifilm X-E Shooters Group

- Fujifilm X Third Party AF lenses Group

- Fujifilm Astrophotography Group

- Viltrox X mount lenses Group

- Fujifilm X-S shooters Group