Merry X mas

Hey there,

I hope Santa Claus was good to you, and put some nice presents under your Christmas tree.

What did I find under my Christmas tree?

Well, our Japanese source put a sweet rumor under my tree, and I am confident that soon enough I will be allowed to unpack it here in front of all FujiRumors readers, hoping you like it.

But today it’s not the time of rumors, but to say something that is surely much more important.

In fact, I would like to sincerely and deeply say merry Christmas to…

- to our amazing sources, who are always helping me to find the right track in the thick rumor jungle, making sure we get an exciting rumor start also in 2020

- to all those, who supported me by using affiliate links or clicking on google banners. It’s really as simple as that: without your help, this blog would have to close tomorrow morning

- to all those FR-readers, who shared Fujifilm news with me, commented kindly, criticized my work constructively, corrected my English ;), voted a survey, shared an article on social media or simply stopped by to read this blog

- to those, who donated a few bucks for free education in Cambodia, by using the paypal donate button on FujiRumors

I am grateful for you, for this community, for this little space on the web and in my life. And today I raise a glass of good red wine for a virtual toast with all of you!

have great holidays… all of you,

You can NO LONGER make donation to FR via Paypal. The paypal link on FujiRumors will redirect you to KNGO, an NGO who gives access to free education to poor kids in Cambodia, and which we raised $5,000 for in the past.

You find the paypal link in the FR sidebar. Donate even just a few bucks helps a lot.

It’s the helpers, who make this world a better place.

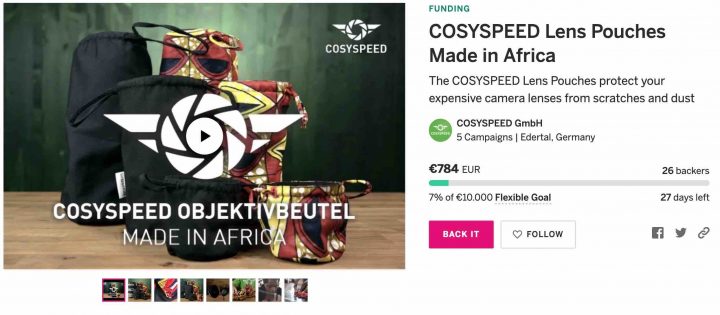

Cosyspeed just launched a nice campaign to support fair trade work in Africa. Check it out at Indiegogo.