TTArtisan AF 56mm f/1.8 for Fujifilm X Mount Autofocus Lens

The new TTArtisan 56mm f/1.8 has just been launched.

It should be available shortly at the official TTArtisan Amazon Storefront here.

In the meantime, you can enjoy the images.

The new TTArtisan 56mm f/1.8 has just been launched.

It should be available shortly at the official TTArtisan Amazon Storefront here.

In the meantime, you can enjoy the images.

TTArtisan has just announced the TTArtisan 27mm f/2.8 Twilight Flame Limited Edition.

It comes with color stickers that you can apply to the camera body to match the lens color.

It should be available shortly at the official TTArtisan Amazon Storefront here.

I own the black version and I have compared it to the Fujinon XF 27mm f/2.8 here.

Get Yours:

The Fujinon XF 56mm f/1.2 R APD is starting to get marked at discounted at stores in Japan as reported by Asobinet here.

This does not come surprising, and here is why.

When Fujifilm launched the original Fujinon XF56mm f/1.2 R (a lens I own too), one of the things that photographers pointed out, is that they would have loved an even smoother and creamier bokeh.

As an answer to this, Fujifilm launched the Fujinon XF56mm f/1.2 R APD with an apodization filter for super smooth bokeh.

But while it delivered buttery smooth bokeh, it had also some shortcomings:

For a full comparison between the original XF56mmF1.2 R and the XF56mmF1.2 R APD check out this article.

There is a third 56mm lens from Fuji, the newer Fujinon XF 56mmF1.2 R WR.

Thanks to its new design, it delivers super smooth bokeh without the need of an APD filter, and hence avoids the shortcomings related to the use of an APD filter (reduced brightness, etc).

With the new XF56mmF1.2 R WR, there is no need anymore for Fujifilm to keep the XF56mmF1.2 R and its APD clone in production, so it does not come surprising that the APD version is slowly disappearing from stores (the non-APD version is starting to get marked as discontinued since January 2023 already).

The Japanese Nikkei has published an article about the Fujifilm Instax business.

Now these are numbers we can only dream of for the digital camera and lenses segment. But the last report we got from Fujifilm about the X/GFX centric performance was quite positive too.

Below I will just list a few articles about what Fujifilm should do to ensure huge success to the X and GFX series going forward.

via Nikkei via Digicame-info

Two Things Fujifilm Should SAVE from their Axed Entry Level Line and Bring to Mid-Range X Cameras

Dear FUJIFILM, We Decided: Make These 6 X-Mount Lenses Next!

Fujifilm Lenses for Wildlife Photography: Fujinon XF 400mmF4 and What Else?

Top 3 Cameras Fujifilm Should Make for Instant Success (X and GFX)

VOTE :: The Ultimate Fujifilm GF Lens Poll – Let Fuji know What You Want!

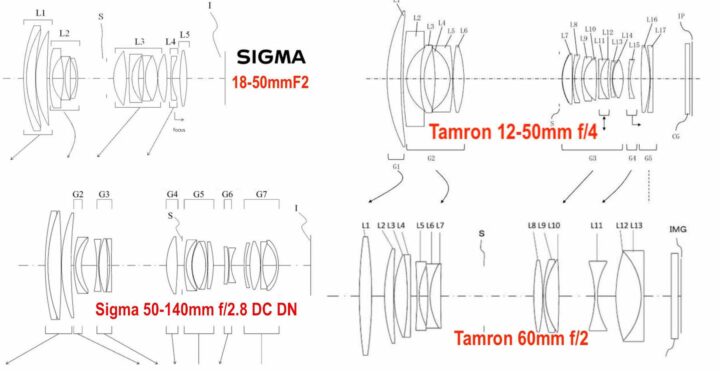

In July we wrote a very popular article about Fujifilm’s future based on patents Fuji has filed.

And of course not only Fujifilm is filing all sorts of patents. Also other brands do.

So out of curiosity I’ve looked back into which APS-C lenses Sigma and Tamron have patented.

Patented APS-C lenses by Sigma and Tamron

Which of the ones above would you like to see become real? Vote below.

But always keep in mind: it’s not said that patents will materialize into a real product, as we explained more precisely here.

All Sigma and Tamron lenses Currently Available for Fujifilm X